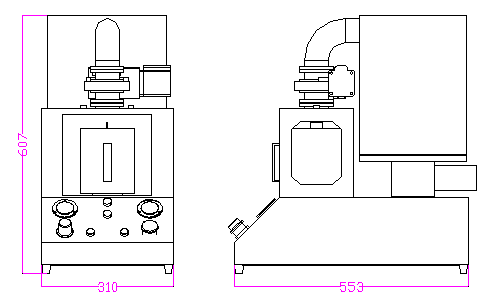

Miihini Wehewehe Kapete , Whakatuwhera Kapene Me te Miihini Paura (CS-Mini)

Whakaahuatanga Poto:

Te Miihini Whakawehe Capsule , Te Whakatuwhera Kapene me te Miihini Paura (CS-Mini) Ko te hoa pai rawa atu o te miihini whakakii kapi, me whai i ia tipu kia kotahi te DECAPSULATOR ●Maapono: Ka hangaia e te Vacuum Decapsulator te jet rangi ki te huri i te 4-5bar hau kapi e whakaratohia ana. ma te puna hau o waho ki roto i te marua o te pupuhi tere.Ko te hau tere-tere ka kumea tonu nga kapene i roto i te ruuma mahi i roto i tetahi waa.Ko te mutunga, ka wehe haere nga kapene;...

Miihini Wehewehe Kapete , Whakatuwhera Kapene me te Miihini Paura (CS-Mini)

Ko te hoa pai rawa atu mo te miihini whakakii kapi, kia kotahi te DECAPSULATOR ia tipu

●Maapono:

Ko te Vacuum Decapsulator te hanga i te jet rangi ki te huri i te 4-5bar hau kōpeke e whakaratohia ana e te puna hau o waho ki te korehau puhoi-tere.Ko te hau tere-tere ka kumea tonu nga kapene i roto i te ruuma mahi i roto i tetahi waa.Ko te mutunga, ka wehe haere nga capsules;ka taka iho te paura, nga pire ranei o roto ki te oko.Na te kaha ngawari hei utu mo te kaha miihini, ka mau tonu nga anga capsule;karekau he kongakonga i hanga i tenei mahi

Kei te waatea tenei decapsulator korehau mo nga kapene rahi katoa, kaore e hiahiatia nga waahanga whakarereke.

●Whakamahinga Tuturu

Ko nga ahuatanga e whai ake nei ka puta mai he potae rereke, me whakamahi DECAPSULATOR ki te hangarua i te paura:

1.I te timatanga o ia wahanga o te hanga tarukino, he mea ngawari ki te puta te whakakii i te paura i te wa e tarai ana i te Miihini Whakakii Capsule, kaore i te whai mana i te wa e kore e taea e te hua te whakatutuki i te hiahia me te paura whakakii.

2.I roto i te hanga o ia ra o nga hinonga ho'oraa, ko nga hua potae kore e tika ana na te mahi rerekee o nga taputapu e tika ana.

3.I roto i te hanga o ia ra o nga hinonga ho'oraa, ko nga hua kapeneta kore e tika ana ka puta mai i nga rauemi mata kino, i nga mahi whakaputa kore ranei.

4. I tua atu, ka whiwhi ano te whare rangahau rongoa hou etahi hua kapi kaore i eke ki nga whakaritenga e tumanakohia ana, me whakapai ake ano i te waa whakamatautau iti o te tarukino hou ki te whakarōpū mo te tauira.

5.I te wa ano, me te piki ake o nga whakaritenga ki te kounga, ka nui ake nga hinonga ka kawemai i nga taputapu miihini e whakamahia ana mo te whakatau i te pauna me te kounga o nga hua kapi i roto i tana ake mahi, na reira ka nui ake nga hua potae kaore e whai mana ki te whai waahi ki te tarai.

●Painga:

• Te paura parakore te whakahoki mai, kaore he anga pakaru.

• Tata ki te 100% te reiti tuwhera kapene.

• Whakaorangia te wa me te moumou.

• Mahi ki nga kapene rereke i te tere tere.

• Kare rawa he kino ki te hiko / pire / papa i roto i te kapene.

• E tika ana ki nga capsules rahi.

• Ko te hau anake te mea whakapiri ki te paura;kore poke.

• Ka taea te whakamahi i nga anga kapi i muri i te wehenga.

• He watea ki te whakahaere, ki te whakanoho me te tiaki.

●Mahinga

| CS Tauira Hangarau Whakatakotoranga | ||||||

| Tauira | CS-mini | CS1 | CS2 | CS3 | CS3-A | CS5 |

| Te Tino Pai | 500caps/min | 700caps/min | 3000caps/min | 1000caps/min | 1000caps/min | 5000caps/min |

| Awhe e tika ana | 000#, 00#, 0#, 0el, 1#, 2#, 3#, 4#, 5# me etahi atu potae pakeke | |||||

| Aratau | Semi-aunoa | Semi-aunoa | Semi-aunoa | Aunoa | Aunoa | Aunoa |

| Te tatari | ā-ringa | ā-ringa | ā-ringa | Aunoa | Aunoa | Aunoa |

| Ngaohiko Mahi | AC100-240V 50-60HZ | |||||

| Whakatauranga Mana | 35W | 35W | 35W | 60W | 60W | 120W |

| Te Raukaha Whare | 1.7L | 1L | 7.5L | 2.3L | 2.3L | 8.5L |

| Ahu(mm) | 607×310×553 | 450×600×650 | 840×420×490 | 500×400×1550 | 500×400×1550 | 650×700×1700 |

| Taumaha | 45kg | 55kg | 80kg | 80kg | 80kg | 150kg |

| Kāhua Mahi | Patene | Patene | Patene | Patene | Mata Pa | Mata Pa |

●Kōhi angamaheni

Neke atu i te 700 nga tipu i Haina kei te whakamahi i a maatau KAUPAPA KAUPAPA ME TE KAUPAPA KAUPAPA!

Mo etahi atu korero, paatohia te hono i raro nei i tukuna e matou te ataata e pa ana ki a Yu Tube