1. Choose proper excipients

After adding some hydrated magnesium silicate into herbal medicine granules, the angle of repose has clearly decreased, fluidity has increased and fill weight variation has narrowed. In the other case, Avicel PH302 as a diluent also narrows the fill weight variation of cyclandelate capsule and increases the fluidity of powder in a tremendous way.

2. Optimize formulations

Not just the change of excipients would solve the fill variation problem, the size of granule and the composition of chemicals also affect the filling result. Some article mentions the ethanol mixed in the granulation process would decrease adsorption of the powder to the filler plate.

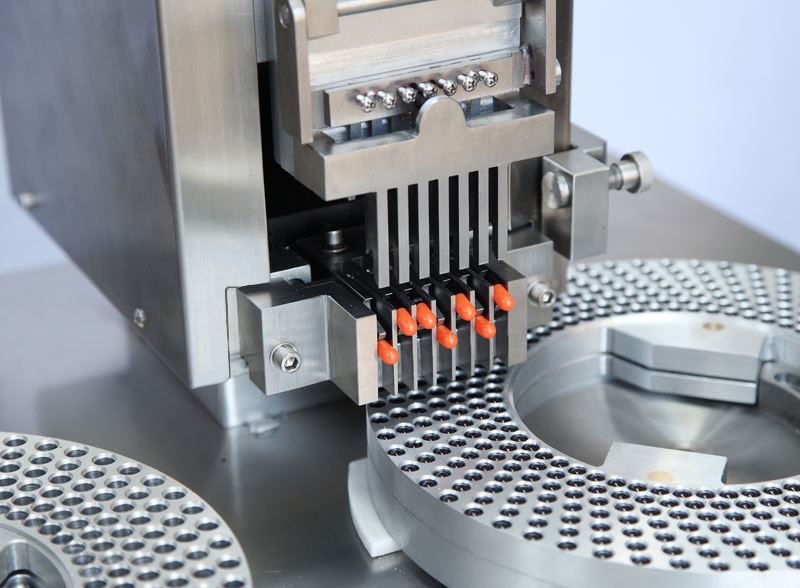

3. Adjust the filler

Capsule filler is important in the production of herbal capsules. Some fillers measure the powder by the measuring plate. Thicker the plate is, more powder is filled and heavier the capsule is. Determine the thickness of the measuring plate and adjust the depth of the filling stick to change the density and conformity of the powder column. Based on this, capsule shells in different sizes need appropriate plate and depth of the filling stick accordingly. Spring, pressure and structure also affect filling results.

4. Environment control

All capsules, especially herbal capsules need to be stored in a stable environment: temperature 18-26℃,humidity 45%-65% and highly purified air.

5. Find machinery solutions

Process monitoring equipment and result testing equipment are accessible for capsule fill weight control. If you feel tired about above methods, a more convenient way is to find the right machine for pharmaceutical production.

Send your message to us:

Post time: Oct-16-2017