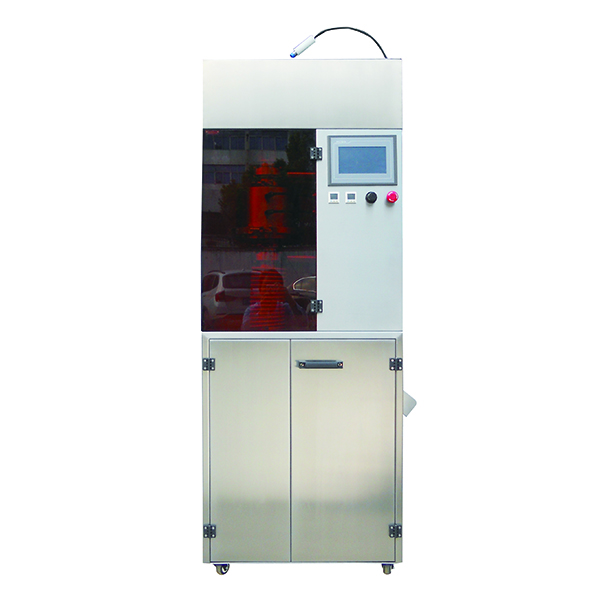

Machine voor het scheiden van capsules, machine voor het openen van capsules en het nemen van poeder (CS5)

Korte beschrijving:

Capsulescheidingsmachine, capsuleopenings- en poederopnamemachine (CS5) De beste partner van een capsulevulmachine, elke plant moet minstens één DECAPSULATOR hebben. ● Principe: de vacuümdecapsulator creëert de luchtstraal om 4-5 bar perslucht van buitenaf te transformeren luchtbron in het hoogfrequente gepulseerde vacuüm.De hoogfrequente gepulseerde lucht zuigt binnen een bepaalde periode continu capsules in de werkkamer.Als gevolg hiervan scheiden de capsules geleidelijk af;poeder of pellet...

Vacuümdecapsulator ---- Capsule-opening en poederopnamemachine

De beste partner voor capsulevulmachines, elke plant moet minstens één DECAPSULATOR hebben

●Principe:

De vacuümdecapsulator creëert een luchtstraal die 4-5 bar perslucht afkomstig van een externe luchtbron omzet in een hoogfrequent gepulseerd vacuüm.De hoogfrequente gepulseerde lucht zuigt binnen een bepaalde periode continu capsules in de werkkamer.Als gevolg,capsules scheiden geleidelijk;poeder of pellets binnenin vallen in het vat.Vanwege flexibele krachten in plaats daarvandoor mechanische krachten blijven de capsuleschalen volledig intact;er is tijdens dit proces geen fragment gemaakt.

Deze vacuümdecapsulator is verkrijgbaar voor capsules van alle maten, er zijn geen vervangende onderdelen nodig.

●Interne weergave:

●Werkelijk gebruik

De volgende situatie zal een abnormale capsule veroorzaken, het is nodig om DECAPSULATOR te gebruiken om poeder te recyclen:

1. In de opstartfase van elke batch medicijnproductie is het gemakkelijk om instabiel poeder te vullen tijdens het debuggen van de capsulevulmachine, ze zijn niet gekwalificeerd terwijl het product niet aan de vereisten kan voldoen met poedervulniveau.

2. Tijdens de dagelijkse productie van farmaceutische bedrijven worden de niet-gekwalificeerde capsuleproducten veroorzaakt door abnormale werking van relevante apparaten.

3. Tijdens de dagelijkse productie van farmaceutische bedrijven worden de niet-gekwalificeerde capsuleproducten veroorzaakt door abnormale grondstoffen of een onstabiel productieproces.

4. Bovendien zal het onderzoeksinstituut voor nieuwe medicijnen ook enkele capsuleproducten hebben die niet aan de verwachte eisen voldeden en die tijdens de kleinschalige testfase van het nieuwe medicijn verder moeten worden verbeterd om te worden gegroepeerd voor formule.

5. Tegelijkertijd zullen steeds meer bedrijven automatiseringsapparatuur importeren die wordt gebruikt voor het bepalen van het gewicht en de kwaliteit van capsuleproducten in hun eigen proces, zodat er meer ongekwalificeerde capsuleproducten zullen zijn die de mogelijkheid hebben om te worden gefilterd

●Voordelen:

• Puur poederherwinning, geen gebroken schelpen.

• Bijna 100% capsule-openpercentage.

• Bespaar tijd en afval.

• Behandel abnormale capsules met hoge snelheid.

• Veroorzaak absoluut geen schade aan de voeding/pellets/tabletten in de capsule.

• Toepasbaar op capsules van elk formaat.

• Lucht is het enige contactmateriaal met poeder;geen vervuiling.

• Bruikbare capsulehulzen na scheiding.

• Gemakkelijk te bedienen, plaatsen en onderhouden.

●Prestaties

| Technische specificaties CS-model | ||||||

| Model | CS-mini | CS1 | CS2 | CS3 | CS3-A | CS5 |

| Maximale efficiëntie | 500 doppen/min | 700 doppen/min | 3000caps/min | 1000 doppen/min | 1000 doppen/min | 5000caps/min |

| Toepasselijk bereik | 000#, 00#, 0#, 0el, 1#, 2#, 3#, 4#, 5# en andere harde capsules | |||||

| Modus | Semi automatisch | Semi automatisch | Semi automatisch | Auto | Auto | Auto |

| Zeven | Handmatig | Handmatig | Handmatig | Auto | Auto | Auto |

| Werkspanning | AC100-240V 50-60HZ | |||||

| Vermogen | 35W | 35W | 35W | 60W | 60W | 120W |

| Kamercapaciteit | 1,7L | 1L | 7,5L | 2,3L | 2,3L | 8,5L |

| Afmetingen (mm) | 607×310×553 | 450×600×650 | 840×420×490 | 500×400×1550 | 500×400×1550 | 650×700×1700 |

| Gewicht | 45 kg | 55 kg | 80 kg | 80 kg | 80 kg | 150 kg |

| Bedieningsstijl | Toetsen | Toetsen | Toetsen | Toetsen | Touch screen | Touch screen |

●Typisch geval

Meer dan 700 fabrieken in China gebruiken onze CAPSULE-OPENINGS- EN POEDERNEMERMACHINE!

Voor meer informatie klikt u op de onderstaande link waar we de relevante video op Yu Tube hebben geüpload