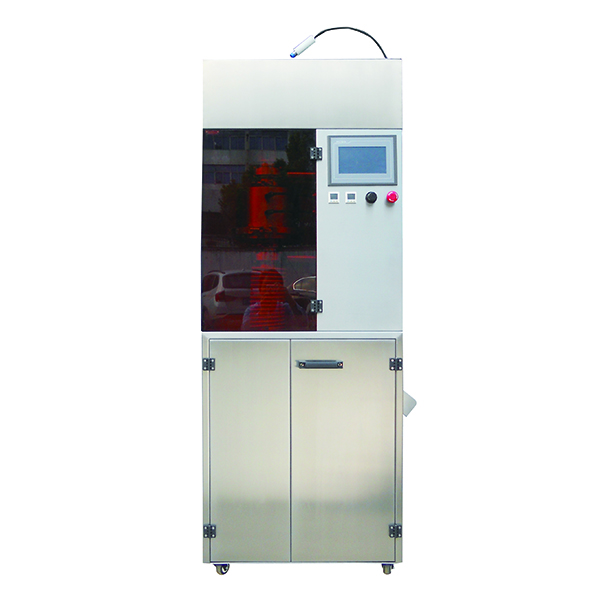

Mochini o Arolang oa Capsule , Mochini o Bulang oa Capsule le Mochini o Nkang Phofo (CS5)

Tlhaloso e Khutšoanyane:

Mochini oa ho Aroha ha Capsule, Mochini oa ho Bula le ho Nka Powder (CS5 ) Molekane ea molemo ka ho fetisisa oa mochine oa ho tlatsa capsule, semela se seng le se seng se lokela ho ba le bonyane DECAPSULATOR ●Molao-motheo: Vacuum Decapsulator e etsa sefofane sa moea ho fetola moea o hatelitsoeng oa 4-5bar o fanoeng ke ka ntle. mohloli oa moea sebakeng se phahameng sa maqhubu a moea.Moea o nang le maqhubu a phahameng o ntse o hula li-capsules ka kamoreng ea ho sebetsa ka nako e itseng.Ka lebaka leo, li-capsules li arohana butle-butle;phofo kapa pellet ...

Vacuum Decapsulator ---- Mochini oa ho Bula le ho Nka Phofo

Molekane ea hloahloa oa mochini o tlatsang capsule, semela se seng le se seng se lokela ho ba le bonyane DECAPSULATOR e le 'ngoe

●Molao-motheo:

Vacuum Decapsulator e theha jete ea moea hore e fetole moea o hatelitsoeng oa 4-5bar o fanoang ke mohloli o kantle oa moea hore e be vacuum ea maqhubu a phahameng haholo.Moea o nang le maqhubu a phahameng o ntse o hula li-capsules ka kamoreng ea ho sebetsa ka nako e itseng.Ka hoo,li-capsules li arohana butle-butle;phofo kapa mapele ka hare a wela fatshe ka moqomong.Ka lebaka la matla a feto-fetohang ho e-na le hooea matla a mochine, likhetla tsa capsule li lula li tiile ka ho feletseng;ha ho sekhechana se entsoeng ts'ebetsong ena.

Vacuum decapsulator ena e fumaneha bakeng sa li-capsules tsa boholo bohle, ha ho na likarolo tse fetohang tse hlokahalang.

● Pono ea ka Hare:

● Tšebeliso ea Sebele

Boemo bo latelang bo tla baka capsule e sa tloaelehang, ho hlokahala ho sebelisa DECAPSULATOR ho tsosolosa phofo:

1.Nakong ea ho qala ha sehlopha se seng le se seng sa tlhahiso ea lithethefatsi, ho bonolo ho hlaha ho tlatsoa ho sa tsitsang ha phofo nakong ea ho lokisa Mochini oa ho Tlatsa Capsule, ha ba tšoanelehe ha sehlahisoa se ke ke sa finyella se hlokahalang ka phofo ea ho tlatsa phofo.

2.Nakong ea tlhahiso ea letsatsi le letsatsi ea likhoebo tsa meriana, lihlahisoa tsa capsule tse sa tšoanelehang li bakoa ke ts'ebetso e sa tloaelehang ea lisebelisoa tse amehang.

3.Nakong ea tlhahiso ea letsatsi le leng le le leng ea likhoebo tsa meriana, lihlahisoa tsa capsule tse sa tšoanelehang li bakoa ke lihlahisoa tse sa tloaelehang kapa mokhoa o sa tsitsang oa tlhahiso.

4. Ho feta moo, setsi sa lipatlisiso sa meriana e mecha se tla boela se be le lihlahisoa tse ling tsa capsule tse hlōlehileng ho finyella litlhoko tse neng li lebeletsoe 'me li hloka ho ntlafatsoa nakong ea liteko tse nyenyane tsa meriana e mecha ho ea ka lihlopha bakeng sa lebese la phofo.

5.Ka nako e ts'oanang, ka litlhoko tse ntseng li eketseha ho ea boleng, likhoebo tse ngata li tla reka thepa ea boiketsetso e sebelisetsoang ho etsa qeto ea boima le boleng ba lihlahisoa tsa capsule ka mokhoa oa eona, kahoo ho tla ba le lihlahisoa tse ngata tse sa tšoaneleheng ho ba le monyetla oa ho hloekisoa.

●Melemo:

• Ho khutlisa phofo e hloekileng, ha ho likhetla tse pshatlehileng.

• Hoo e ka bang 100% tekanyo e bulehileng ea capsule.

• Boloka nako le tshenyo.

• Sebetsana le li-capsules tse sa tloaelehang ka lebelo le phahameng.

• Ho etsa hore ho hang ha ho na kotsi ho matla / pellets / matlapa ka hare ho capsule.

• E sebetsa ho li-capsules leha e le life tse boholo.

• Moea ke oona feela lintho tse amanang le phofo;ha ho tshilafalo.

• Likhetla tsa capsule tse ka sebelisoang ka mor'a ho arohana.

• E bonolo ho sebetsa, ho beha le ho hlokomela.

●Ts'ebetso

| Litlhaloso tsa Tekheniki tsa Mohlala oa CS | ||||||

| Mohlala | CS-mininyane | CS1 | CS2 | CS3 | CS3-A | CS5 |

| Bokhoni bo Phahameng | 500caps/min | 700caps/min | 3000caps/min | 1000caps/min | 1000caps/min | 5000caps/min |

| Range e sebetsang | 000#, 00#, 0#, 0el, 1#, 2#, 3#, 4#, 5# le li-capsules tse ling tse thata | |||||

| Mokhoa | Semi-auto | Semi-auto | Semi-auto | Auto | Auto | Auto |

| Sieving | Bukana | Bukana | Bukana | Auto | Auto | Auto |

| Voltage e sebetsang | AC100-240V 50-60HZ | |||||

| Tekanyetso ea Matla | 35W | 35W | 35W | 60W | 60W | 120W |

| Bokhoni ba Chamber | 1.7L | 1L | 7.5L | 2.3L | 2.3L | 8.5L |

| Litekanyo(mm) | 607×310×553 | 450×600×650 | 840×420×490 | 500×400×1550 | 500×400×1550 | 650×700×1700 |

| Boima ba 'mele | 45kg | 55kg | 80kg | 80kg | 80kg | 150kg |

| Mokhoa oa ho sebetsa | Likonopo | Likonopo | Likonopo | Likonopo | Skrine se thetsoang | Skrine se thetsoang |

● Nyeoe e tloaelehileng

Limela tse fetang 700 naheng ea China li sebelisa MACHINE oa rona oa HO Bula LE HO NKA PORO!

Ho tseba haholoanyane, ka kopo, tobetsa sehokelo se ka tlase moo re kentseng video e nepahetseng ho Yu Tube